Inspired by the surrounding beauty of the Pocono Mountains, two local businessmen spoke about standing up a new business combining locally harvested hazard timber with 100% recycled materials to produce sustainable, functional and affordable Indoor and Weatherproof Outdoor Battery-Powered Table Lamps. With over 80 years of combined design and manufacturing expertise and a desire to build a business to support their local community, a concept was born. Fortunately concept led to reality...

Innovative Lamps Sustainably Made...

-

Rustic Farmhouse Battery Powered LIVE EDGE WOOD Table Lamps

No Electrical Outlet? No Problem! Our 28" Tall WIRELESS BATTERY-OPERATED TABLE LAMP...

-

Rustic Farmhouse Battery Powered ROUGH SAWN TIMBER BEAM Table Lamps

No Electrical Outlet? No Problem! Our 28" Tall WIRELESS BATTERY-OPERATED TABLE LAMP...

-

Modern Farmhouse Battery Powered LIVE EDGE WOOD Table Lamps

No Electrical Outlet? No Problem! Our 28" Tall Cordless BATTERY-POWERED TABLE LAMP...

-

Rustic Farmhouse ROUGH SAWN BARN WOOD Battery Powered Table LampS

No Electrical Outlet? No Problem! Our 28" Tall Cordless BATTERY-POWERED TABLE LAMP...

Facility Tour

Green Mountain Live Edge is Where Technology & Hybrid Design Meets Old Growth Timber.

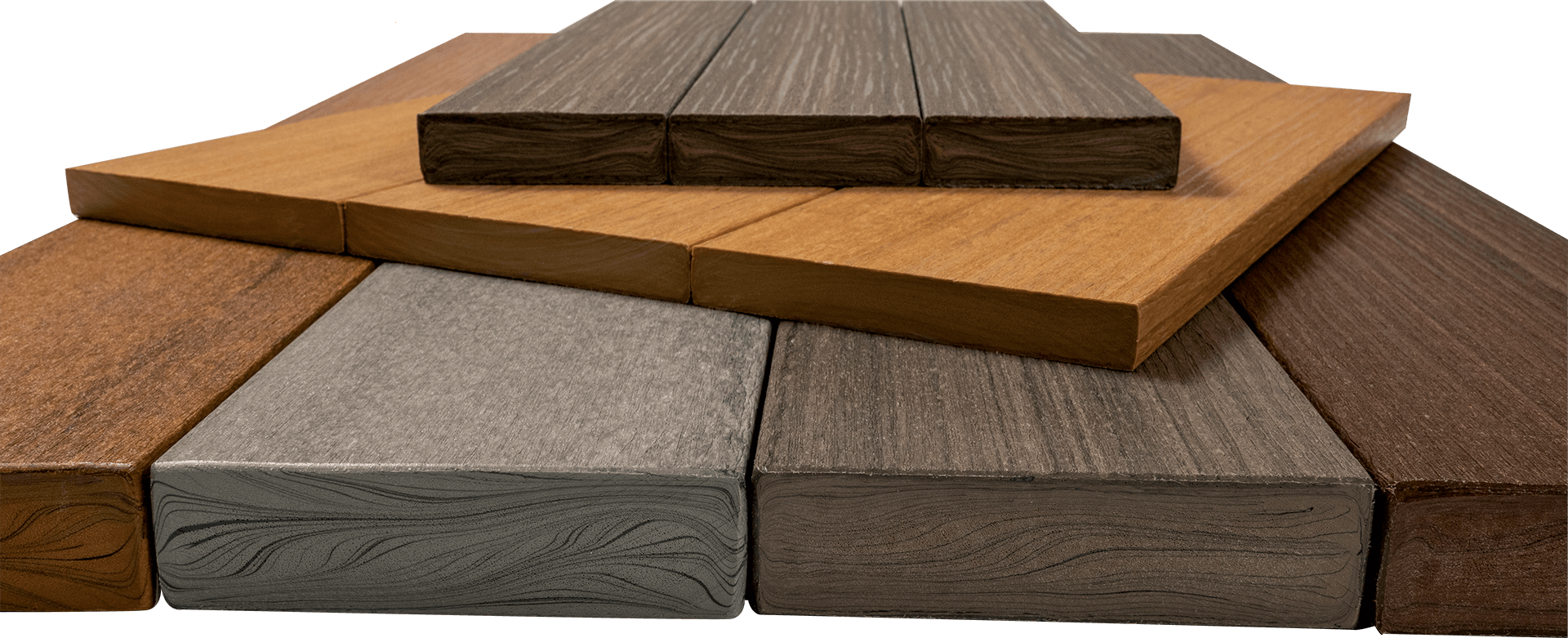

Green Mountain Live Edge Inc produces functional, sustainable and affordable Live Edge Wood and Poly Lumber Wireless Table Lamps We have developed proprietary materials and processes, combining technology, design and old growth timber to offer our customers with one-of-a-kind products.